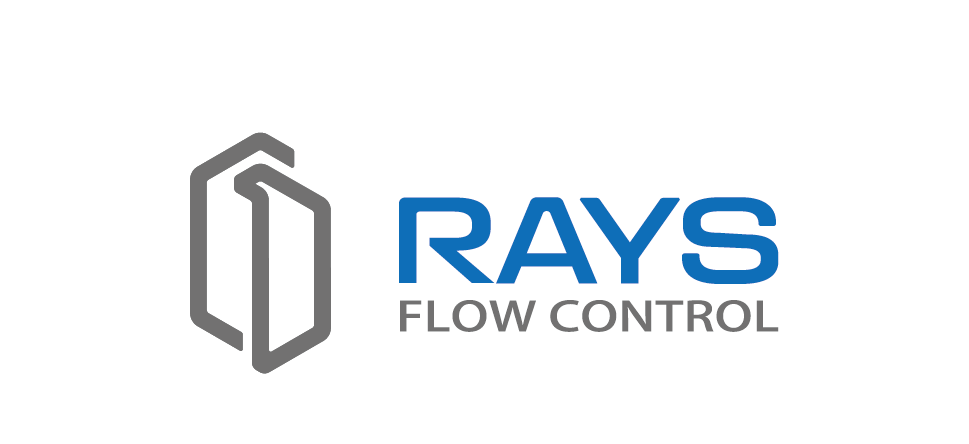

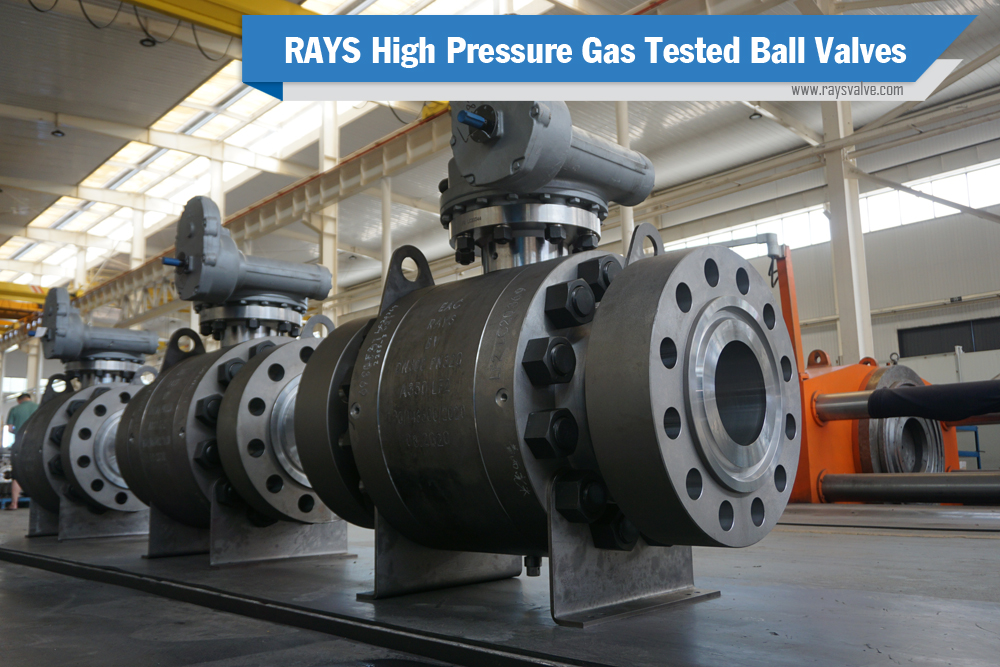

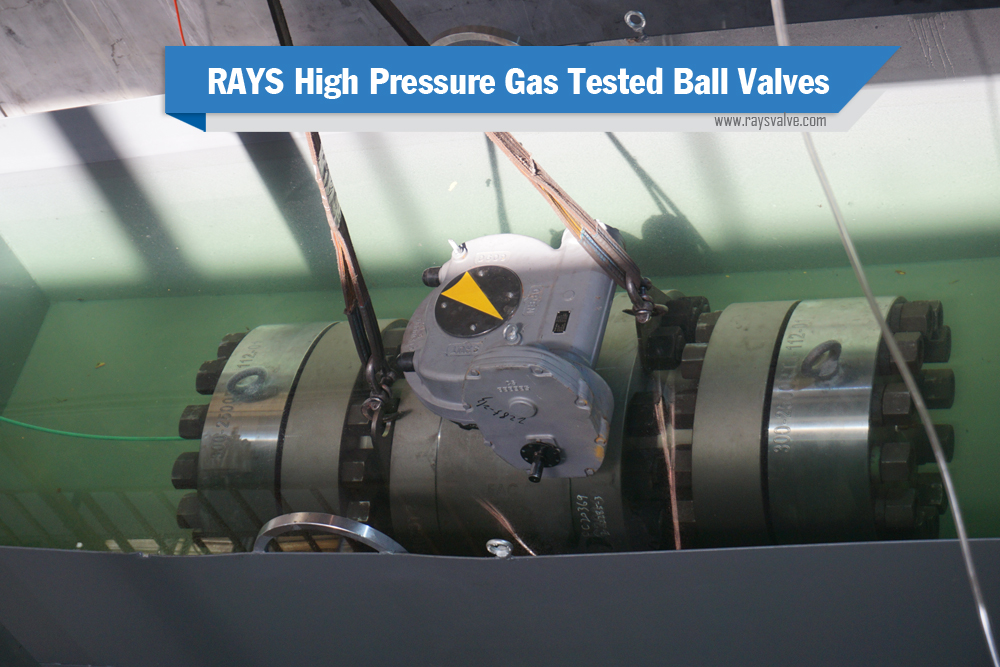

Recently, a batch of high-pressure pipeline ball valves of DN250-DN400 PN63-PN320 have been successfully completed in our RAYS factory. DN250 PN320 and DN300 PN320 passed the high-pressure nitrogen test of 32MPa for three cycles to meet the requirements in harsh working conditions. The DN400 PN63 metal seated ball valve passed the high-pressure nitrogen test of 6.3MPa for three cycles, and all products meet the Grade A zero leakage requirement in harsh working conditions. This batch of products will be delivered to Russia in upcoming days at an ambient temperature of minus 60 degrees Celsius YAMAL project put into use.

- Product introduction

Special purpose metal seated ball valves and high-pressure pipeline ball valves are suitable for Class150 ~ Class2500, PN16 ~ PN420 various pipelines, used to cut off or connect the medium in pipelines. Through the choice of: carbon steel, stainless steel, alloy steel and other valve material – special purpose metal seated ball valve and high-pressure pipeline ball valve can be applied to water, steam, oil, nitric acid, acetic acid, oxidizing medium, urea and other media. Manual, worm drive, pneumatic or electric operations are available according to customer needs.

The high-pressure pipeline ball valve is designed and manufactured by: absorbing foreign high-pressure pipeline ball valves technology, adopting special sealing structure, using reliable sealing performance, realizing zero leakage truly, and passing the high-pressure gas zero leakage test requirements. Special purpose metal seated ball valve is designed and manufactured with our special structure, which can realize zero leakage. The ball and seat of the metal seated ball valve for special purpose have good shearing self-cleaning function, which eliminates the phenomenon of stuck resistance caused by dust particles sticking to the valve seal, and keeps the appearance of the conventional metal seated ball valve. The seal of this metal seated ball valve produced by RAYS is processed by supersonic flame spraying tungsten carbide superwear-resistant alloy technology. It has the properties of high hardness and ultra-normal wear resistance where the hardness is up to HRC65~80. Its service life is far longer than the traditional hard sealed ball valve, which is suitable for: organosilicon, polysilicon project, and other special working condition systems.

- Structural features

RAYS developed and produced a special use metal seated ball valve with: the advanced supersonic spraying, nickel-based flame spray ball, and seat hardening technology. This is to prevent the valve at high temperatures rise to death, scraper device, such as patent structure, good sealing performance, completely fireproof structure design, natural anti-static structure design, the function of blocking and discharge etc., solved the hard particle medium under harsh conditions for sphere wear-resisting coating wear easily, fall off, medium coking, valve stuck, short service life, to ensure that the metal seated ball valve wear-resisting reliable seal under various temperature and pressure.

- Quality assurance

QA from the design of ball valves to the procurement, processing, assembly, testing, subsequent surface treatment, packaging, and shipping. This is not only to meet the company’s quality system requirements, but also for the third-party agencies/customer end-users to witness at the same time. Also, this is to ensure that every valve can meet all quality requirements when leaving the factory.

- Applicable standard specifications

Design and manufacturing standards: API 6D, API 608, BS 5351, GB/T 21385

Structural length standard: ASME B 16.10, GB/T 12221, GOST 28908

Connecting flange standard: ASME B 16.5, GOST 33259, GB, JB, HG, SH, BS, DIN, JIS, etc.

Test standard: API6D, API 598, GB/T 13927, GB/T 26480, JB/T9092, ISO 5208 GOST 9544