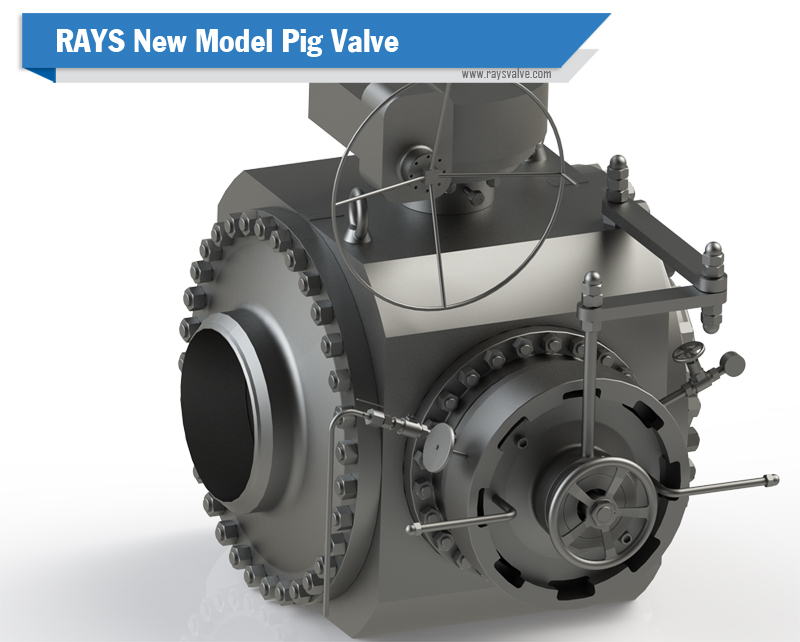

Recently, RAYS successfully delivered a new C-type PIG VALVE for a foreign end-user, which will be used in an important pipeline project in the Arctic, contributing to the global energy strategy.

The PIG VALVE is a new type of valve that serves as a transmitting and receiving device for pipe cleaners, and it also functions as a universal ball valve.

With the use of pig valve and the corresponding pipe cleaners, pipe cleaning, emptying, isolation and sequential transport of media, testing of piping systems, etc. can be done more easily with the use of a pig valve and the corresponding pipe cleaners.

Features of the RAYS new C-type PIG VALVE:

- Ball hole area is about 21% larger than the pipe diameter area, to ensure the continuous flow of the conveyed medium during the pipe cleaning operation

- Realization of two different calibers connected for pipe cleaning

- Valve Stem is not subject to ball thrust & the stem twist

- Quick-open blind operation is

- The valve seat provides zero leakage with DBB & DIB-1 function.

- Interlock design to ensure the safety of

- Fire-safe design based on API 6FA and API 607 standard

- Anti-static design & Anti-blowout stem design

The technical innovation of RAYS new C-type PIG VALVE

a) The ball is equipped with a “sending and receiving cylinder” structure:

The ball cavity is equipped with a “sending and receiving cylinder”, which can be applied to both rubber pipe cleaners and electronic pipe cleaners, expanding the scope of use of the pipe cleaning valve.

b) The functional design of the drain valve:

The drain hole is added to the wall of the pipe channel of the pipe cleaning valve and a drainage valve is installed on the hole. When the pipe cleaning valve receives the pipe cleaner, this drainage valve is opened and the dirt cleaned by the pipe cleaner is discharged. This improves the working environment when receiving (cleaning) the pipe cleaner.

c) The function of the pressure relief valve is increased:

The new type has a small pressure relief ball valve installed on the side of the entire pipe cleaning valve, with a warning sign to indicate. In the valve cavity, pressure release at the same time can also discharge the oil in the cavity of the clearing valve which has a dual function.

d) The new structure design of quick release valve cover:

The quick-release valve cover part is one of the key parts of the pipe cleaner valve.

It is directly related to the safety and labor intensity of the receiving and firing operation process of the pipe cleaner.

e) The new structure design of quick release valve cover:

The quick-release valve cover part is one of the key parts of the pipe cleaner valve. It is directly related to the safety and labor intensity of the receiving and firing operation process of the pipe cleaner.

The new C-type PIG VALVE cleverly adopts the “side opening handwheel, a positive handwheel, and a pull rod” side opening mechanism, so that the “rotation and pull” of the valve cover parts become easy and comfortable, with flexible operation and accurate positioning characteristics.

More about PIG VALVE design and construction.

1. Overview

1. Main purpose.

The best way to transport oil and gas is by pipeline, which has the advantages of high transport efficiency, low cost, low losses, and low environmental pollution.

To ensure the safety, efficiency, and smoothness of pipeline transportation, it is necessary to use the “pipe cleaner” to clean the pipeline. The “pig valve” and “pipe cleaner” together form a pipe cleaning operation device. It can be used as both the launch receiving device and the opening & closing valve of the pipe cleaner, which is called the “pipe cleaner launch receiving valve”. (abbreviated as “pipe cleaner”).

Its main uses are:

- Before the new pipeline is put into operation, remove all kinds of residues in the pipe to make the pipeline unobstructed.

- Rust removal and anticorrosion coating on the inner wall of new

- Do regular oil pipe scraping wax and gas pipe de-watering on the put into the production It can maintain an effective transmission capacity for a long time. At the same time, reduce the corrosion in the pipe wall and extend the service life of the pipeline.

- It can be used as an isolation and quality exchange of different kinds of media conveyed in the same

- Pipeline water pressure before exhaust and water pressure test after 2、Basic parameters.

- Nominal diameter: 2″-24″ (DN50-DN600)

- Nominal pressure Class150-2500(PN1.6-42.0MPa)

- Applicable: -196-400℃ (different materials use different temperatures)

- Applicable media: oil, oil products, natural gas containing sulfur, purified natural gas, as well as gas, water, and other media.

2. Main types of products.

The main types of products are mainly three types according to product function, usage, and pipe cleaning valve.

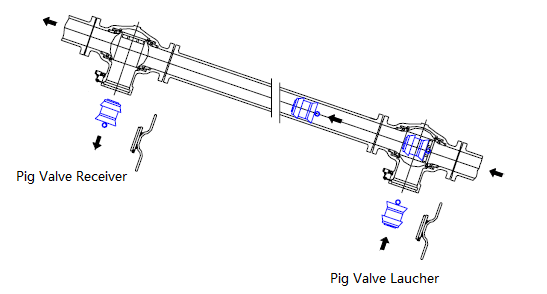

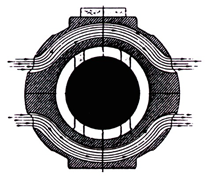

- B type of pipe cleaning valve: pipe cleaner launch and receive the whole process of fluid flow without suspension. See figure (2)

Figure (2) B type pipe Pig Valve

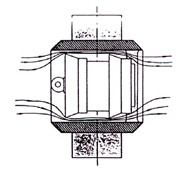

- C type: The fluid is not interrupted when the cleaner is launched and enters the cleaning valve, but when the pig was removed, the flow was interrupted briefly. (See Figure (1))

Figure (1) C type pipe cleaning valve

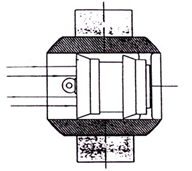

- PS type Pig Valve: The fluid flow is interrupted for a short period during both launching and receiving purge, and the PS type is used when different types are transported in sequence or prevent mixing of transported (See Figure (3))

Figure (3) S type Pig Valve

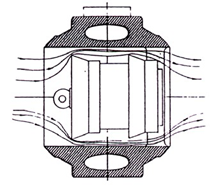

2. structural features and working principle

- Structural features. The structural features of the cleaning valve are innovatively designed after adapting and increasing the functions based on the structural principle of the three-way ball valve.

- Working principle. The working principle of pipe cleaning valve is: the pipe cleaner is placed (or received) in the inner cavity of the sphere of the pipe cleaning valve, through the sphere in the “┴”- shaped (inverted “┬á” three-way valve body with mutual vertical, for reciprocal 90 ° rotation movement. When the sphering channel and the pipeline channel are on the same axis, the pipe cleaner is launched and received by the pipe cleaner valve under the fluid pressure in the pipeline, and its working principle is shown below. the principle is shown as follows.