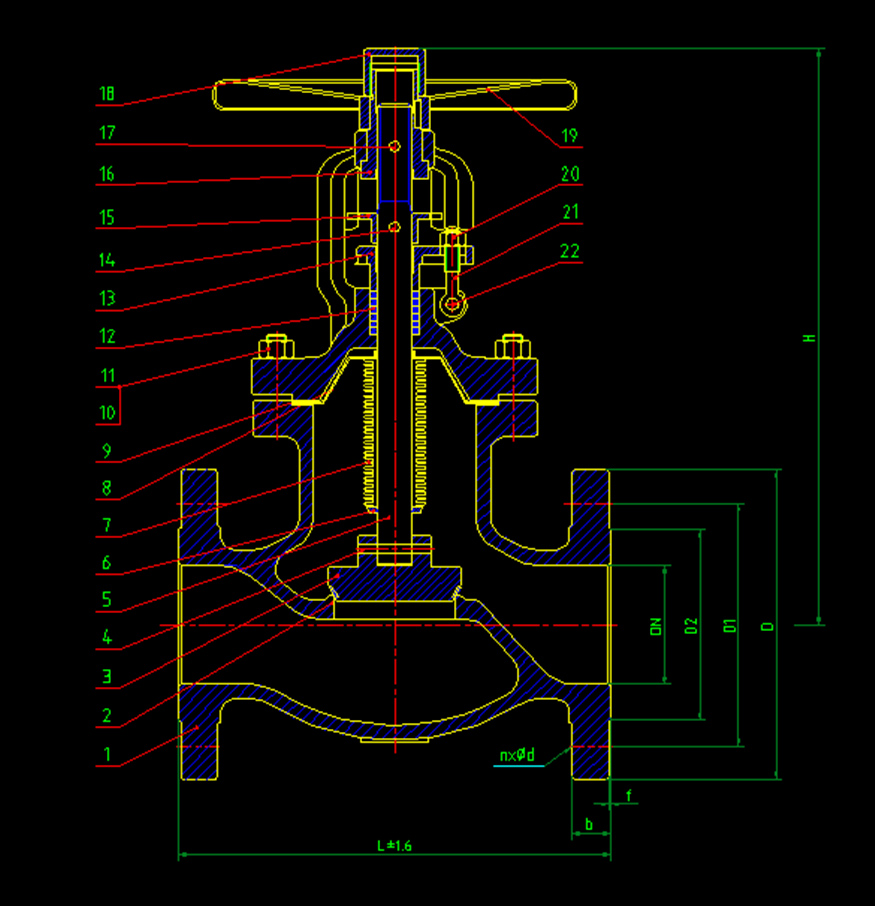

RAYS bellows sealed globe valve adopts international advanced technology and double sealing design. It has the characteristics of high-performance elastic metal bellows and extremely long expansion fatigue life. Pipe shut-off valves: improve the use of energy efficiency, increase the safety of production equipment, reduce maintenance costs & frequent maintenance, and also provide a clean & safe work environment.

Bellows sealed globe valve are suitable for class 150~2500, working temperature -46°C~538°C pipeline. Using carbon steel, stainless steel and other different main materials can be suitable for various media. The optional drive devices are: hand wheel, electric, pneumatic, etc.

Bellows sealed globe valves are suitable for pipelines under various working conditions in petroleum, chemical, pharmaceutical, fertilizer, electric power, and other industries.

Design

Applicable Standards:

DESIGN & MANUFACTURE CONFORM WITH: EN 13709, ASME B16.34

CONNECTION DIMENSION CONFORMS WTIH: EN 1092, ASME B16.5

INSPECTION & TEST CONFORMS WITH: EN 588-1, DIN 3202, ASME B16.10

MATERIAL CONFORMS WITH: EN 12266, ISO 5208, API 598

Features and Application:

Bellows globe valve adopts sealed stucture.In common valves, the packing seal of the stem ages fast and it is easy to leak,but this design totally eliminates these short comings.Apart from increaseing the efficiency of materials and the safety of production equipment,it not only reduces maintenance the costs and frequent maintenance of products but also provides a clean and safe working environment. Double seal design(bellows and packings),if the bellows invalidates,the stem packings will prevent outside leaking. There are no fluid loss,but it reduces the energy loss and improves the equipment safety. Longer service life,less maintenace and lower operating costs. Firm and durable seal design of bellows ensures the zero leakage of stem and provides more reliable performance and no maintenance. Quenched stem and surface nitridation with good performance of corrosion and friction resistance. Excellent performance,graceful outline,and more visibleness with position indicating of stem.

Applicable Standards:

| Body Disc Bellow Stem Bonnet Bolt Nut Gland Bushng Stem Nut Gasket Packing |

GS-C25/WCB/CF8M/CF8/CF3M/CF3/CD3MN A105/F316/F304/F316L/F304L/F51 304/316/316L/304L/S31803 F6a/F304/F316/F304L/F316L/F51/Monel GS-C25/WCB/CF8M/CF8/CF3M/CF3/CD3MN B7M/B8M/L7M/B16M 2HM/8M/7M/4M 410/304/316/304L/316L C95200/D2/A536 Flexible graphite+304/Flexible graphite+316 Flexible graphite |

*Materials could be choosed according to customers’ requirement & working condition.