There is no excerpt because this is a protected post.…

RAYS Will Participate In NEFTEGAZ 2024

RAYS Will Participate In NEFTEGAZ 2024 RAYS will participate in the Moscow International Oiland GasExhibition (NEFTEGAZ) in Russia from April 15 to 18, 2024. The exhibition is set to feature 1,800 exhibitors from 41 countries around the world, making it one of the top ten oil exhibitions in the world and the largest trade exhibition in Russia’s oil and gas industry. The event is endorsed and sponsored by various organizations such as the Russian Ministry of Energy, the Ministry…

RAYS Successfully Deliver Large Size Fully Welded Ball Valves

RAYS Successfully Deliver Large Size Fully Welded Ball Valves RAYS Flow Control has successfully delivered a remarkable order of 49 pieces DN 1000 PN100 Large Fully Welded Ball Valves. This delivery is a testament to RAYS’ engineering expertise and unwavering commitment to quality when it comes to producing large-scale industrial valves. Each fully welded ball valve weighing over 20 tons showcases RAYS’ engineering skills and dedication to making high-quality industrial valves on a large scale. RAYS expedited the fulfillment…

RAYS Pneumatic Control Butterfly Valve

Pneumatic Control Butterfly Valve Recently, THE RAYS has provided a batch of high-performance Pneumatic Control Butterfly Valves to our end user, a famous oil & gas production company, providing it with excellent and reliable industrial valve solutions at ultra-low temperatures of -52°C. Harsh environment to ensure stable operation of the production facility in the production, storage and condensation of liquefied natural gas. The following are its main technical parameters and features: Technical Parameters Product Type: Pneumatic Butterfly Valve Size Range: DN50mm to DN600mm Pressure Level: CL150~CL1500 PN6~PN250 Operating Temperature: From -60°C…

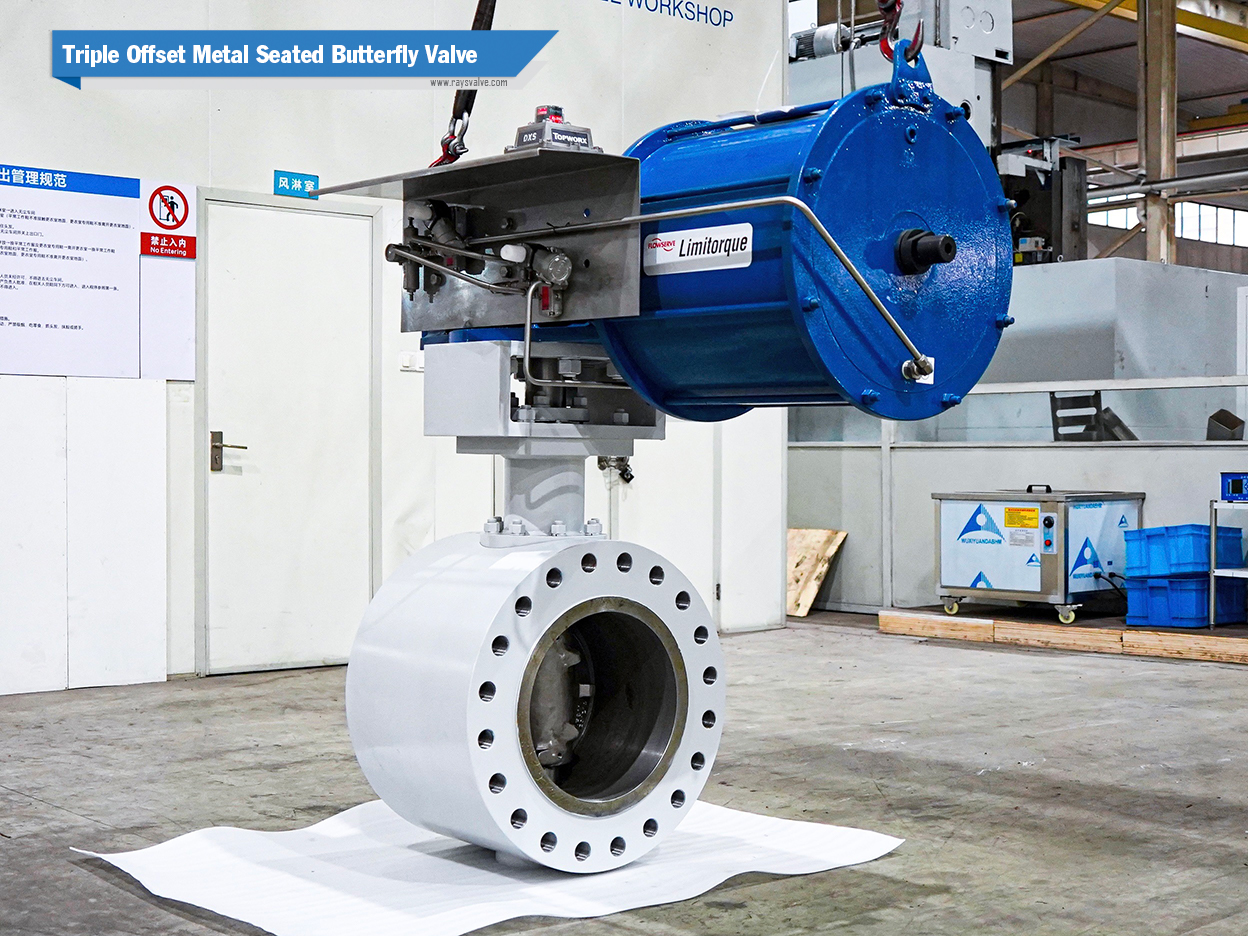

RAYS Triple Offset Metal Seated Butterfly Valve

Triple Offset Metal Seated Butterfly Valve Triple Offset Butterfly Seated Valves are a type of high-performance butterfly valve, also known as triple eccentric metal-seated butterfly valves. These valves are designed with a triple offset structure that provides tight sealing characteristics, making them excellent for high-pressure and high-temperature applications. Technical Parameters Product Type: Triple Offset Metal Seated Butterfly Valve Size Range: DN50-DN1200 or 2″-48″ Pressure Rating: From 150LB to 2500LB Operating Temperature: From -196°C to 650°C Connection Type:RF, BW, LUG,Wafer…

New RAYS Alpha Production Facility(U/C) in Wenzhou

ALPHA PRODUCTION FACILITY In the first half of 2024, RAYS will complete the construction of the Wenzhou Alpha production facility and gradually put into operation. At that time, it will accommodate about 300 professional and technical workers, and the annual output can reach 15,000 tons. The Alpha production facility is a strategic expansion of RAYS in recent years, aiming to expand production capacity and meet customer needs with higher quality and higher standards of delivery. The facility is located at…

Pneumatic-Hydraulic Actuated Ball Valves

Pneumatic-Hydraulic Actuated Ball Valves Our Pneumatic-Hydraulic Actuated Ball Valves are a high-performance valve solution suitable for a variety of natural gas and petroleum applications. Here are its main technical parameters and features: Technical Parameters Product Type: Pneumatic-Hydraulic Actuated Ball Valve Size Range: DN 50mm to DN 1500mm Pressure Rating: From 150LB to 2500LB Operating Temperature: From -46°C to -60°C Connection Type: BW, RF, RTJ, etc. Material: Options include Carbon Steel, Stainless Steel, etc. Suitable Medium: Suitable for natural gas, petroleum, etc.…

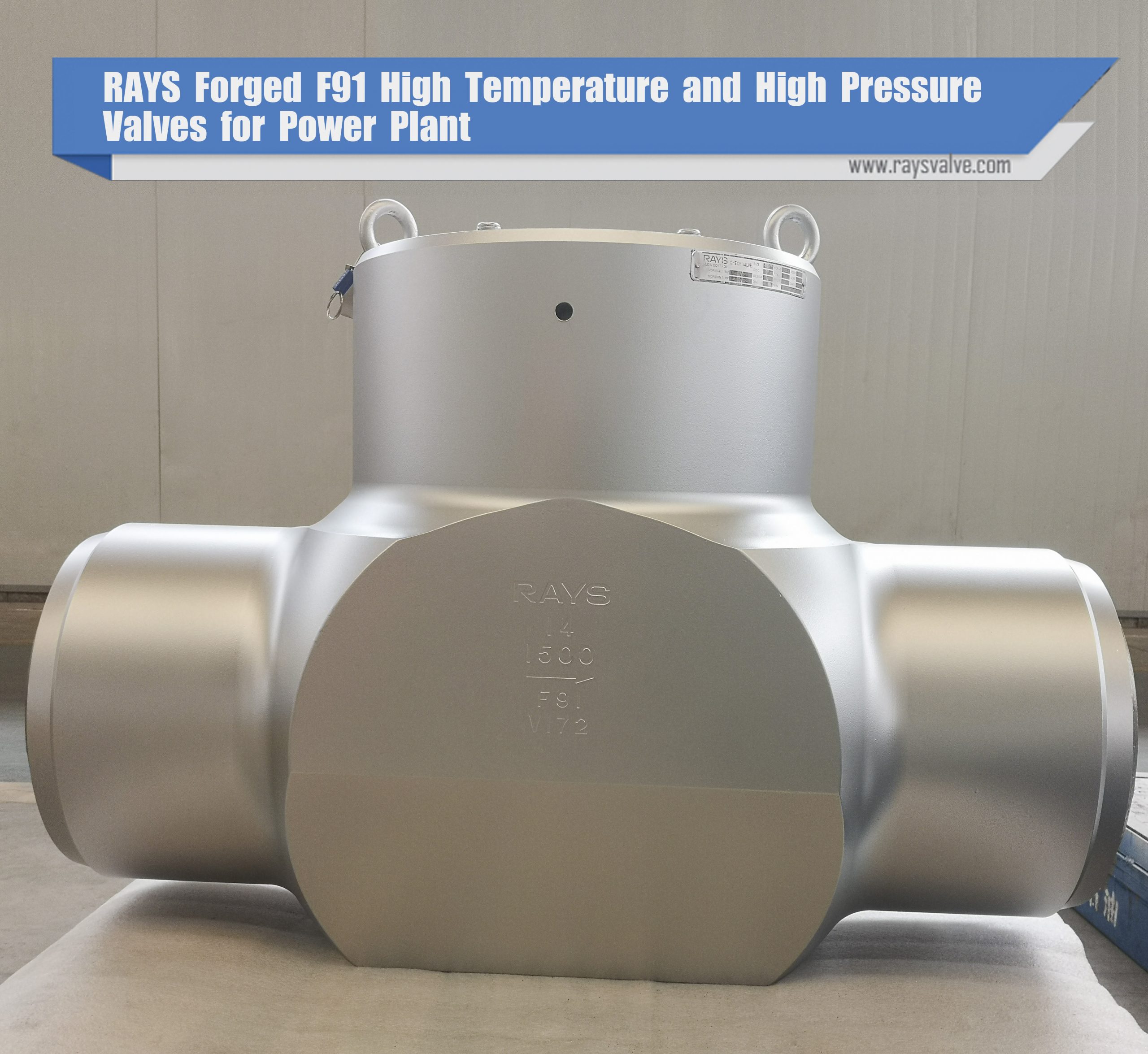

High Pressure and High Temperature Gate Valve in Malaysia

RAYS recently delivered high pressure and high temperature gate valves and check valve for the project based in Malaysia. The middle cavity of the valve adopts a pressure self-tightening sealing structure. The higher the inner cavity pressure, the better the sealing performance. Both ends of the branch pipe are welded structures, which are suitable for different connection requirements. The sealing surfaces of the gate and valve seat are made of stellite cobalt-based cemented carbide, which has: good wear…

Wear-Resistant Ball Valve

Relying on the high-tech senior engineering team of RAYS, the wear-resistant ball valve independently developed by RAYS has truly achieved zero leakage and its’ service life has reached the world’s advanced level. Advanced ball and seat hardening technology In order to ensure that the valve can adapt to: high, low temperature, and particle conditions; the ball and seat sealing surface of RAYS wear-resistant ball valve adopts advanced sealing surface hardening technology. This includes: supersonic spraying, metallurgical melting spraying, surface envoy…

Emergency Shutdown Forged Steel Ball Valve

Emergency Shutdown Forged Steel ball Valve Background/work conditions of this project: The Emergency shutdown forged steel ball valve supplied by RAYS FLOW CONTROL to an offshore processing facility in Kazakhstan are ready to ship。 Before this project,the customer of this project has been using an emergency shutdown ball valve imported from Europe and the United States. After a productive discussion with the customer, we have formulated the most suitable product design plan for them. With RAYS’long-term experience in design…