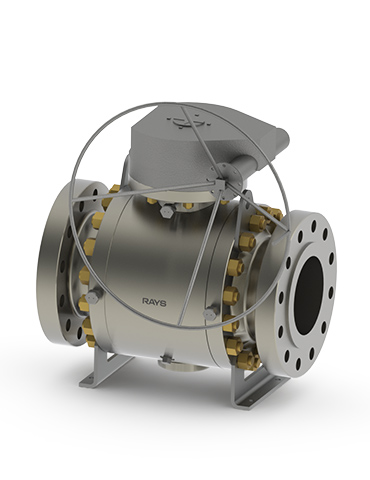

Design

RAYS steel ball valves are designed manufactured to provide maximum service life and dependability. All ball valves are full ported and meet the design requirements of American Petroleum Institute standard API 608&API 6D British standard BS 5351 and generally conform to American society of Mechanical Engineers standard ASME B16.34 valves are available in a complete range of body/bonnet materials and trims.

Range of Materials

Standard body/bonnet materials include nine grades of carbon, low alloy and stainless steel, for special applications they can be supplied in other grades of ally and stainless steel, there’s a full range of trim materials to match any service optional packing and gasket materials are available for a full range of service conditions.

Applicable Standards

● STEEL BALL VALVES API 608/API 6D

● STEEL BALL VALVES ISO 14313

● FIRE SAFE,API 607

● ANTI STATICS,API 608

● STEEL VALVES,ASME B16.34

● FACE TO FACE ASME B16.10

● END FLANGES,ASME B16.5

● BUTTWELDING ENDS ASME B16.25

● INSPECTION AND TEST, API 598/ API 6D

Design descriptions

● FULL PORT DESIGN

● BB.BOLTED BONNET.SPLIT BODY

● THREE PIECES BODY FOR 12″ & ABOVE

● TRUNNION MOUNTED BALL TYPE

● BLOW-OUT PROOF STEM

● FIRE SAFE CONSTRUCTION

● ANTI STATICS DEVICE

● STOPPER DEVICE

● ISO 5211 MOUNTING PAD

● FLANGED OR BUTTWELDING ENDS

● AVAILABLE WITH WG OPERATOR