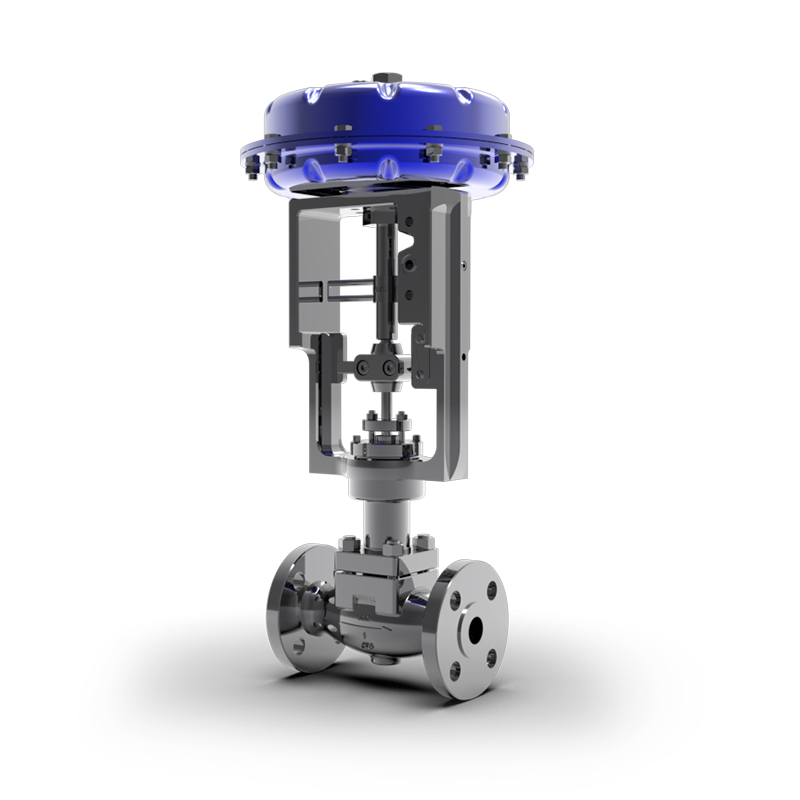

CS702 Small-size Cage-guided Control Valve

The CS702 Small-size Cage-guided Control Valve is a high-performance single-seat regulating valve, suitable for high-pressure differential situations where the liquid pressure difference exceeds 3 MPa. It is widely used in self-control systems of industries such as petroleum, chemical engineering, metallurgy, power stations, air separation equipment, liquefied natural gas, etc. The sturdy valve core guide and sleeve can prevent liquid from undergoing flash evaporation and cavitation. The valve body has an S-shaped streamlined channel, with low pressure drop loss, large flow rate, and a wide adjustable range.

CS702 Small-size Cage-guided Control Valve

The CS702 Small-size Cage-guided Control Valve is a high-performance single-seat regulating valve, suitable for high-pressure differential situations where the liquid pressure difference exceeds 3 MPa. It is widely used in self-control systems of industries such as petroleum, chemical engineering, metallurgy, power stations, air separation equipment, liquefied natural gas, etc. The sturdy valve core guide and sleeve can prevent liquid from undergoing flash evaporation and cavitation. The valve body has an S-shaped streamlined channel, with low pressure drop loss, large flow rate, and a wide adjustable range.

C702-2 Unbalanced Cage-guided Globe Control Valve

The C702-2 Unbalanced Cage-guided Globe Control Valve is a single sleeve type regulating valve. The valve core does not have a pressure balance hole. The valve body has a compact structure, the fluid channel is in an S-shaped streamline, and it is equipped with a guide wing to improve the smooth flow of the fluid around the sleeve. The pressure drop loss is small, the flow rate is large, the adjustable range is wide, it is resistant to cavitation corrosion, and the accuracy of the flow characteristic curve is high.

C702-2 Unbalanced Cage-guided Globe Control Valve

The C702-2 Unbalanced Cage-guided Globe Control Valve is a single sleeve type regulating valve. The valve core does not have a pressure balance hole. The valve body has a compact structure, the fluid channel is in an S-shaped streamline, and it is equipped with a guide wing to improve the smooth flow of the fluid around the sleeve. The pressure drop loss is small, the flow rate is large, the adjustable range is wide, it is resistant to cavitation corrosion, and the accuracy of the flow characteristic curve is high.

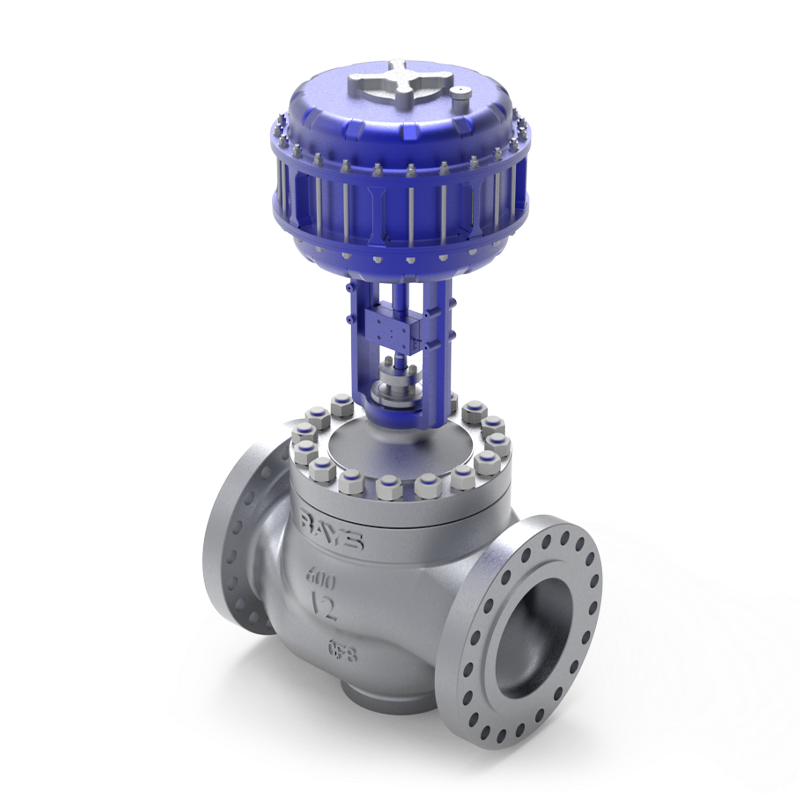

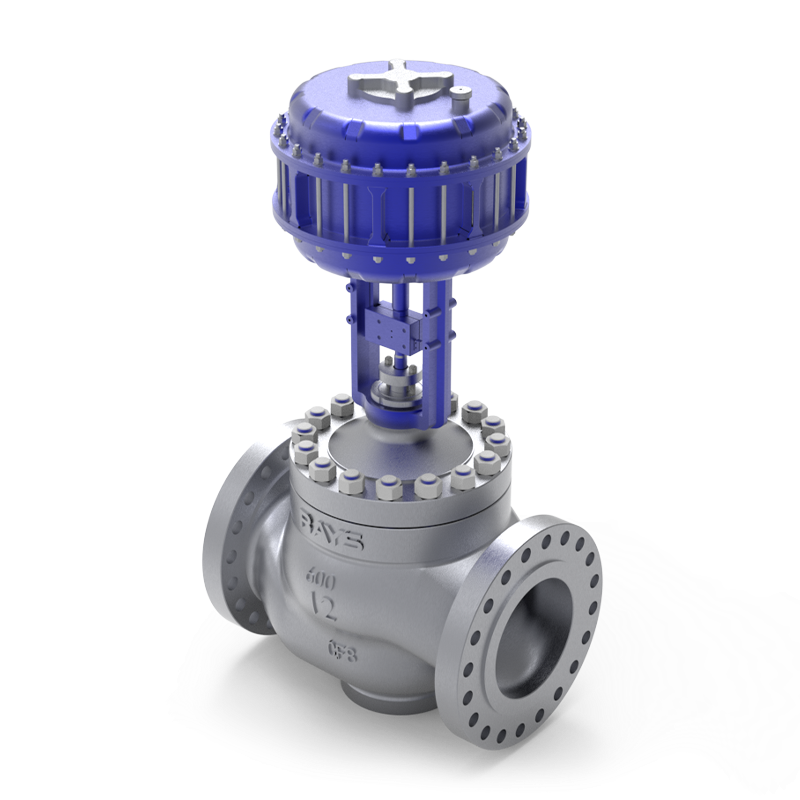

CH702 High-pressure Cage-guided Control Valve

The CH702 High-pressure Cage-guided Control Valve is a pressure-balancing type regulating valve. This valve is widely applicable to high-pressure drop scenarios that require good dynamic stability, low noise, and minimal cavitation corrosion. The fluid passage of the valve body is in an S-shaped streamline, resulting in low pressure drop loss, large flow rate, and a wide adjustable range.

CJ702 Jacketed Cage-guided Control Valve

The CJ702 Jacketed Cage-guided Control Valve is a derivative product of the C702 cage-type control valve. When the crystallization temperature of the regulated medium is higher than the normal temperature, or due to the decrease in temperature and the increase in fluid viscosity or solidification, the valve fails to operate properly, the valve can be heated and insulated with steam to prevent material crystallization and solidification, avoiding valve blockage and reducing the power consumption of the project. This valve not only has the advantages and applications of the CJ702 cage-type control valve, but also has the function of insulating the regulated medium.

CT702 Cage-guided Control Valve with Pilot

The CT702 Cage-guided Control Valve with Pilot is a pressure-balancing type control valve. The valve internals adopt a sleeve-guided pilot-type valve core. It is suitable for controlling high-pressure differential fluids at various temperatures. The valve core moves rapidly by utilizing the pressure of the fluid, with low operating force. The sealing type is a single-seat seal, and the accuracy of the flow characteristic curve is high. The dynamic stability of the control valve is good, the noise is low, and it is dust-proof.

This series of products features a compact structure, small size, and S-shaped fluid channels. The valve core adopts a pressure-balancing structure, with high accuracy of the flow characteristic curve and the ability to achieve a larger CV. It can be quickly replaced, is stable and reliable, and is easy to maintain. A smaller actuating force can control a high pressure difference. There is a sealing ring between the valve core and the valve cage, significantly reducing the leakage. It is equipped with the RSMF series multi-spring pneumatic diaphragm actuator, which has a large thrust, strong steel strength, sensitive action, high-precision positioning, fast response, convenient and sturdy, and a long service life.

Developed with principles of standardization, universality, modularity, and interchangeability. Valves of different sizes maximize part interchangeability, universality, and ease of maintenance. This ensures low operational costs.

Material: WCB, WCC, LCB, LCC, WC6, WC9, CF8, CF8M, CF3, CF3M...

Nominal Size: DN25、DN40、DN50、DN65、DN80、DN100、DN150、DN200、DN250、DN300、DN350、DN400、DN450、DN500、DN600、DN700

Pressure Rate: PN16, PN25, PN40, PN63, PN100, PN20, PN50, PN110, CL150, CL300, CL600

High Pressure:CL900 、CL1500 、CL2500

Operating Temperature:Standard Temperature: -17℃~+230℃

High-temperature EI:+230℃~+525℃

Low-temperature LE-I:-45℃~-17℃

LE-II:-100℃~-45℃

LE-III:-196℃~-100℃

Operator: Pneumatic,Electric, Manual, Electrohydraulic, etc...

Application range: Suitable for switching the flow direction of the medium in pipeline systems such as water supply, petrochemical, metallurgy, mining, textile, energy, paper, food, steel, etc. Also, for shunting or mixing fluids.

The valve body is made of high-strength alloy steel or stainless steel, and is equipped with a precisely processed swing-type valve disc structure, enabling automatic control of the unidirectional flow of the medium. The optimized fluid dynamics design effectively reduces water hammer impact. The surface of the valve disc is clad with hard alloy to ensure reliable sealing under high-pressure and high-speed conditions. It is suitable for pipeline systems in industries such as petroleum, chemical engineering, and power.

RAYS' rising stem ball valve is designed to operate without friction between the ball and the seat during opening and to achieve zero leakage when closed. This makes it well-suited for demanding conditions. The valve is made entirely of metal and is fire-resistant, capable of functioning in extreme temperatures ranging from -196°C (320.8°F) to 538°C (1000.4°F). It can handle media with particulates like sand and short fibers, and meets NACE standards for corrosion resistance, ensuring it can resist sulfide stress cracking in harsh environments. The valve also features a self-cleaning mechanism. When the ball is tilted away from the seat, the fluid flows 360° around the ball's sealing surface, effectively removing any debris. This prevents damage from high-speed fluid flows and keeps the sealing area clean. The rising stem ball valve is ideal for various applications including exhaust, fluid transfer, pipeline isolation, bypass, product segmentation, and emergency shutdowns, particularly where high switching frequencies and zero leakage in high temperatures are required.

RAYS Three-Way and Multi-Port Ball Valve are important components in fluid control systems and are widely used in various industrial fields. They are variants of ball valves. Their design allows fluids to be distributed or converted between more than two pipes. The three-way ball valve has three interfaces, which can realize the diversion, confluence or switching of fluids. According to the different internal structures, it is divided into L-type and T-type. The L-type can only connect two mutually orthogonal pipes, and cannot simultaneously maintain the interconnection of the third pipe, and only plays a distribution role; the T-type can make three orthogonal pipes interconnected and cut off the third channel, playing a diversion and confluence role. The multi-way ball valve is an extension of the three-way ball valve, with more interfaces and more complex fluid control functions.