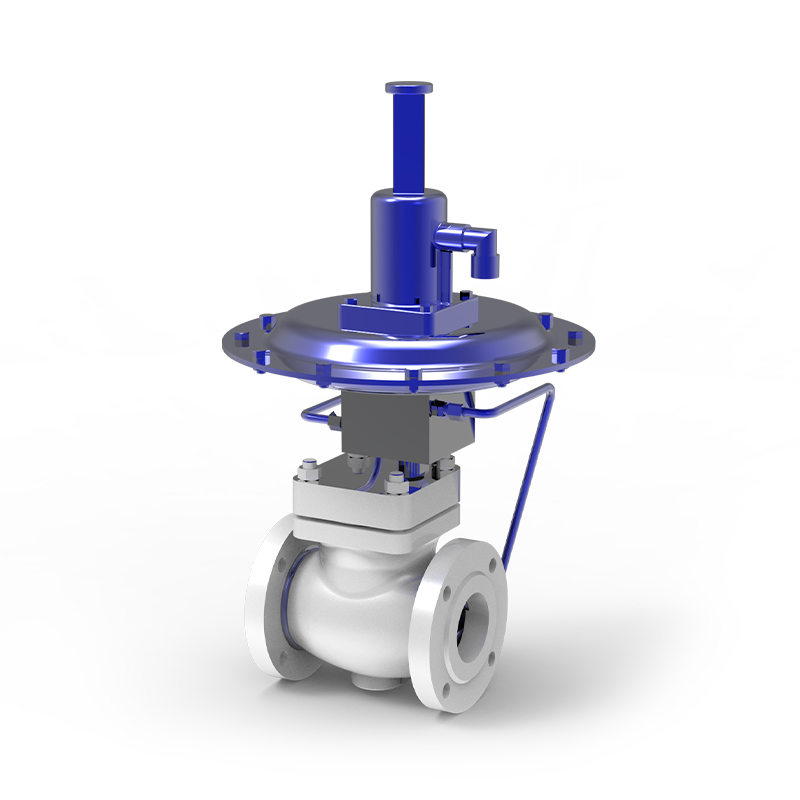

SO-25109 Self-operated Low-pressure Relief Regulator

An energy-saving control valve without external energy sources can be widely used in gas sealing devices of nitrogen-sealed storage tanks for non-corrosive gases with a pressure relief range of 0.1 to 10 KPa and a working temperature not exceeding 150℃. It can also be applied to low-pressure or vacuum safety protection systems in industries such as ships, natural gas, oxygen production, and blowers. The structure is simple, installation and debugging are convenient, maintenance costs are low, the pressure regulation range is wide, and it can be adjusted in three grades within the range of 1.0 to 10 KPa. The response speed is fast, and the regulation accuracy is low.

Self-Operated Micro-Pressure Regulator does not require additional driving energy and is a kind of energy-saving control device; it is a specialized product for current most popular nitrogen sealing system of storage tanks.

Material: WCB、WCC、LCB、LCC、CF8、CF8M、CF3、CF3M

Nominal Size: DN15~100

Pressure Rate: PN1.6~4.0MPa

Temperature Range: ≤150℃

Voltage Regulating Range:0.14~0.36Kpa 、 0.32~1.0Kpa 、0.9~2.5Kpa 、2.1~4.5Kpa 、3.9~7.2Kpa

Operator: Self-venting type

Application range: Suitable for use in pipeline systems in industries such as water supply, petrochemicals, metallurgy, mining, textiles, energy, papermaking, food, and steel, for switching the flow direction of the medium, as well as for splitting or mixing the medium flow.

The Non-Rising Stem Gate Valve is also called the rotating stem gate valve. Stem and nut are arranged on the gate plate, handwheel rotation drive valve stem rotate to lift the gate, usually there is a trapezoidal thread at the bottom of the valve stem and the rotation movement is turned into a linear motion through the limit slot between the valve stem and the gate body and the gate body and the gate, that is, the operation torque is turned into operation thrust. When the valve is turned on, when the height of the gate is equal to the diameter of the valve 1: 1: 1, the channel of the fluid is completely unblocked, but at the run, this position cannot be monitored. In actual use, the vertex of the valve stem is used as a sign, that is, the position that is unmoved as its full opening position. The non-rising stem gate valve has the design characteristics of the ordinary wedge-type gate valve. The valve body has a guide mechanism, which can prevent the gate from rotating when the gate is turned on or closed, ensuring that the seal of the gate on the valve seat is accurate accordingly. At the same time, the wedge valve does not rub with the valve seat before turning off, thereby reducing the wear of the cover and effectively extending the service life of the valve.

The Side Entry Cryogenic Trunnion Mounted Ball Valve fixed ball valve is a type of fixed ball valve that adopts an upper mounted structure. The ball is installed and disassembled through the upper part of the valve body, and can work stably under ultra-low temperature conditions. When closed, the valve stem drives the ball to rotate, making the hole on the ball perpendicular to the valve body channel, thereby cutting off the medium; When opened, the valve stem drives the ball to rotate 90 °, aligning the hole on the ball with the valve body channel, and the medium can pass through.

RAYS cast steel check valves are designed and manufactured to provide maximum service life and dependability. All check valves meet the design requirements of American Petroleum Institute standard API600 & 6D.BS EN 13709 and generally conform to American Society of Mechanical Engineers standard ASME B16.34. Valves are available in a complete range of body/cover materials and trims.