、

、

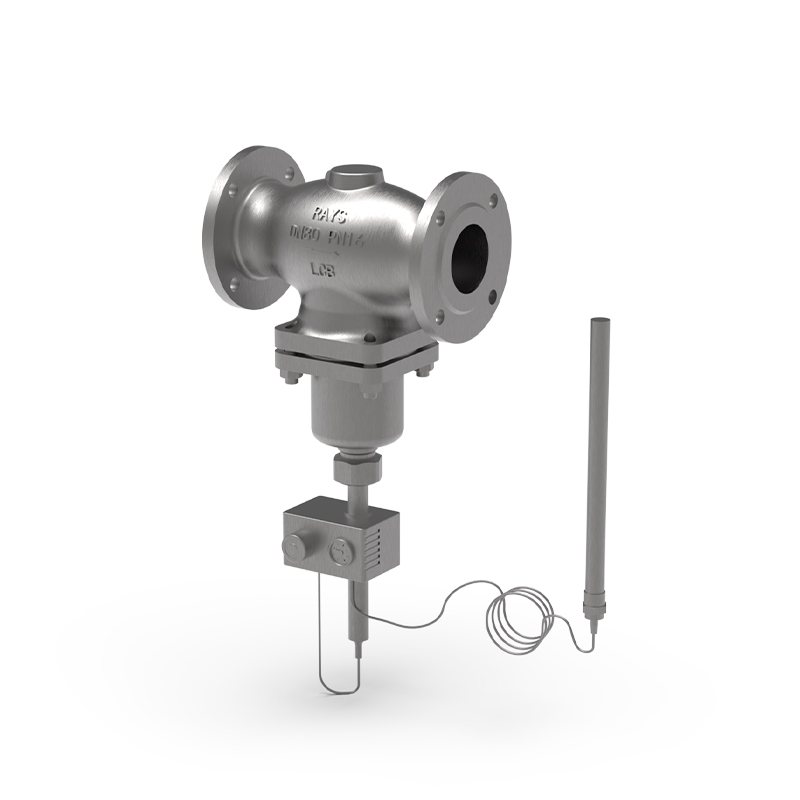

SO-33006、SO-33106、SO-33017、SO-33117 Self-operated Temperature Regulator (Heating Type)

An energy-saving control valve without external energy sources, used for temperature control of various heaters for non-corrosive liquids, gases and steam, etc.

SO-34006、SO-34106、SO-34017、SO-34117 Self-operated Temperature Regulator (Cooling Type)

An energy-saving control valve without external energy sources, used for temperature control of various heaters for non-corrosive liquids, gases and steam, etc.

Self-operated Temperature Regulator is an energy-saving control device that does not require external driving energy. It relies on the temperature of the medium being regulated as the power source and the changes in the medium to automatically adjust according to the preset value. It integrates detection, control and execution functions into one valve and forms an independent instrument control system.

1. The Self-operated Temperature Regulator is developed by absorbing advanced foreign technology. Key components are imported products, featuring superior performance and reliable quality. It belongs to an energy-saving control system.

2. The Self-operated Temperature Regulator adopts a stainless steel bellows pressure balance valve core to reduce the force on the valve core when the pressure before and after the valve changes. Moreover, it uses an "O" ring sealed valve stem, which has less friction compared to the packing seal form used in similar products, which is conducive to improving control accuracy.

3. The temperature controllers of the heating type (temperature-closed type) temperature control valve and the cooling type (temperature-open type) temperature control valve can be interchanged, demonstrating strong versatility.

The temperature controller adopts a gas bag type over-temperature protection structure, allowing an over-temperature of 100℃, which is far superior to the spring type over-temperature protection (40℃) mostly used both domestically and internationally.

Material: WCB、WCC、LCB、LCC、CF8、CF8M、CF3、CF3M

Nominal Size: DN15~125mm

Pressure Rate: PN1.6~4.0MPa

Temperature Range: ≤350℃

Operator: It relies on the temperature change of the medium being regulated itself as the power source.

Application range: It is applicable to the temperature control of non-corrosive liquids, gases and vapors in industrial sectors such as petrochemical, metallurgy, chemical engineering, energy, papermaking and light industry, as well as urban centralized heating and heating systems, with a temperature range of +80℃ to +300℃.

The quality of forged steel parts is higher than that of cast steel parts, and they can withstand the impact of beatings. The plasticity, toughness, and other mechanical properties are higher than those of cast steel parts. The diameter of cast steel gate valves is generally not more than DN80, and most of them are reduced-diameter designs. Compared with cast steel gate valves of the same diameter, the flow rate is slightly lower, but the pressure and temperature range they can withstand are higher than those of cast steel valves, and the sealing performance is much better than that of cast steel gate valves, and the service life is longer. The flow direction of the medium is not restricted like other gate valves.

Stop Check Valve, A multi-purpose valve that functions as both a stop valve and a check valve. Its structure is similar to that of a globe valve, but the stem and disc are not fixed. When the stem is lowered and the disc is pressed tightly on the seat, it acts as a stop valve; After the stem rises, the check valve acts. On lines that require both a stop valve (or gate valve) and a check valve (such as the outlet of a water pump), using a stop check valve can save installation costs and space. In the opening and closing process, because the friction between the valve disc and the sealing surface of the valve body is smaller than that of the gate valve, it is more wear-resistant.

The valve body is made of high-strength alloy steel or stainless steel, and is equipped with a precisely processed swing-type valve disc structure, enabling automatic control of the unidirectional flow of the medium. The optimized fluid dynamics design effectively reduces water hammer impact. The surface of the valve disc is clad with hard alloy to ensure reliable sealing under high-pressure and high-speed conditions. It is suitable for pipeline systems in industries such as petroleum, chemical engineering, and power.