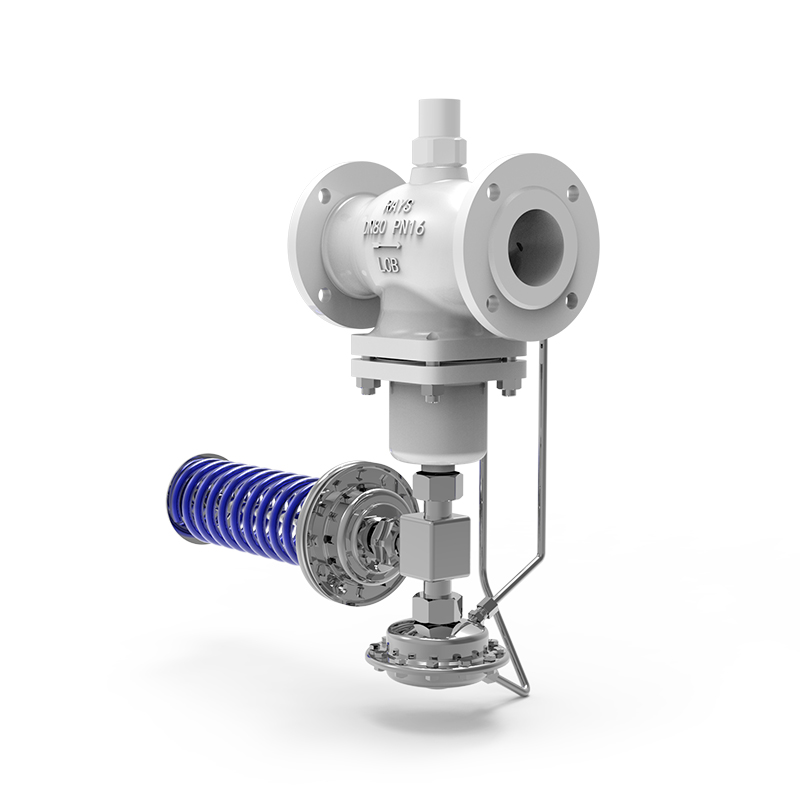

SO-13700/FT06、SO-13710/FT06、SO-13700/FT17、SO-13710/FT17 Combined Self-operated Flow and Temperature Regulator

An energy-saving multi-combination control valve without external energy sources, used as a flow and temperature control device for non-corrosive liquids, gases and steam and other media with a maximum temperature of 200℃.

SO-133001/ZA3、SO-133101/ZA3 Combined Self-operated Pressure and Differential Pressure Regulator

An energy-saving multi-combination control valve without external energy sources, used for pressure and differential pressure control of non-corrosive liquids, gases and steam and other media with a maximum temperature of 350℃.

SO-137001/ZA3、SO-137101/ZA3 Combined Self-operated Flow and Pressure Regulator

An energy-saving multi-combination control valve without external energy sources, used for controlling the flow and pressure of non-corrosive water and other liquid media with a maximum temperature of 200℃

An energy-saving multi-combination control valve without external energy sources, used for flow and temperature control devices for non-corrosive liquids with a maximum temperature of 350℃, as well as pressure and differential pressure control devices, and flow and pressure control devices for liquids, gases and steam.

Does not require any external driving energy

Has pressure balancing function and high sensitivity

Does not require maintenance, with reliable performance

Low noise, smooth operation

Adopts modular design, with high levels of standardization, seriesization and generalization

Can be combined into various types of self-operated regulating valves through components

Material: WCB、CF8、CF8M

Nominal Size: DN15~250mm

Pressure Rate: PN1.6~4.0MPa

Voltage Regulating Range:0.02MPa,0.05MPa、 0.3~1.2MPa、0.1~0.6MPa、0.015~0.15MPa、 0.05~0.3MPa、0.01~0.07MPa、0.025~0.035MPa、0.8~1.6MPa

Temperature Range: ≤350℃

Operator: Self-pressurization type

Application range: It is applicable to the automatic control systems in industrial production processes such as water supply, petrochemical, heating and cooling, energy, papermaking, food, and steel, where there is no (or cannot be used) driving energy. It is particularly suitable for automatic control system devices in gas production and transportation or gas supply and transportation.

RAYS Top Entry Cryogenic C-Type Ball Valve is a specially designed ball valve suitable for ultra-low temperature environments, especially for the control of cryogenic fluid media such as liquefied natural gas (LNG), liquid oxygen, and liquid nitrogen. The characteristic of the top entry C-Type C-Type ball valve lies in its special structural design.

The Comodity Cast Steel Gate Valve is mainly composed of valve body, valve cover, valve wedge, valve seat and valve stem. The two sealing surfaces are wedge-shaped gate valves. The purpose of the wedge is to improve the auxiliary seal load, to achieve both high medium pressure sealing and low medium pressure sealing. The valve body of the wedge valve is provided with a guide mechanism, which can prevent the gate from rotating when the gate is turned on or closed, ensuring that the seal of the gate on the valve seat is accurate accordingly. At the same time, the wedge valve does not rub with the valve seat before turning off, thereby reducing the wear of the cover and effectively extending the service life of the valve.

The working principle of the three eccentric butterfly valve is based on its unique structural design, which achieves sealing and flow control functions through three eccentric distances: Structural Design: Three Eccentric Structure: The valve stem axis deviates from the center of the butterfly plate and the body center, and the rotation axis of the valve seat is at an angle to the axis of the valve body channel. This design enables the butterfly plate to form a wedge-shaped space with the valve seat when closed, achieving sealing through friction. Conical Sealing Surface: The periphery of the butterfly plate is machined into an external inclined conical surface, and the valve seat is an internal inclined conical surface, forming an elliptical contact surface. When closed, the butterfly plate achieves sealing through the asymmetric pressing force in the up and down directions, and the sealing becomes tighter as the pressure increases. Working Mechanism: Open State: The butterfly plate is separated from the valve seat, and the fluid passes through the channel; due to the eccentric design, during the opening process, the butterfly plate gradually detaches from the valve seat, reducing friction and operating torque. Closed State: The butterfly plate rotates 90° to contact the valve seat, forming a wedge-shaped space and achieving sealing through torque. Flow Regulation: During the opening rotation of the butterfly plate, the valve's flow area gradually increases, reducing fluid resistance and improving the flow coefficient, achieving flow regulation. Technical Advantages: Sealing Performance: The metal-to-metal hard sealing method can still maintain good sealing performance in high-temperature and high-pressure environments; Low Friction Operation: The eccentric design significantly reduces the operating torque and extends the valve's lifespan; Self-Locking Function: When closed, the butterfly plate becomes tighter under pressure, preventing the phenomenon of over-positioning. This valve is widely used in the petroleum, chemical, and power industries, and common structural connection forms include double flange type, welding type, lug type, and socket type, etc.