CS701 Small Diameter Single Seat Regulating Valve

The CS701 Small Diameter Single Seat Regulating Valve is suitable for controlling fluids under various pressures and temperatures. It is widely used in self-control systems of industries such as petroleum, chemical engineering, metallurgy, power stations, air separation equipment, liquefied natural gas, etc. The valve body has an S-shaped streamlined channel, with low pressure drop loss, large flow capacity, wide adjustable range, and high accuracy of flow characteristics.

C701 Single-seat Control Valve

The C701 single-seat control valve is a top-guided single-seat valve, widely used in automatic control systems of industries such as petroleum, chemical engineering, metallurgy, power stations, air separation equipment, liquefied natural gas, etc. The valve body is compact in structure, has a small shape, the fluid passage is in an S-flow line shape, the pressure drop loss is small, the flow rate is large, the adjustable range is wide, the flow characteristic curve has high accuracy, the valve core guiding area is large, and the vibration resistance is good.

CM701 Micro-flow Single-seat Control Valve

The CM701 Micro-flow Single-seat Control Valve is suitable for regulating the small flow of various fluids under different pressures and temperatures. It is widely used in automatic control systems of industries such as petroleum, chemical engineering, metallurgy, power stations, air separation equipment, liquefied natural gas, etc. The valve body has an S-shaped streamlined channel, with low pressure drop loss, wide adjustable range, and high accuracy of flow characteristics.

C702-1 Cage-guided Single-seat Control Valve

The C702-1Cage-guided Single-seat Control Valve is a high-performance single-seat control valve, widely used in the automatic control systems of industries such as petroleum, chemical engineering, metallurgy, power stations, air separation equipment, liquefied natural gas, etc. The valve body has a compact structure, with a S-shaped flow channel, a large guiding area for the valve core, excellent vibration resistance, low pressure drop loss, large flow capacity, and a wide adjustable range. The sturdy sleeve protects the valve body from damage caused by flash evaporation and cavitation, and is suitable for applications where flash evaporation and cavitation occur due to high pressure differences.

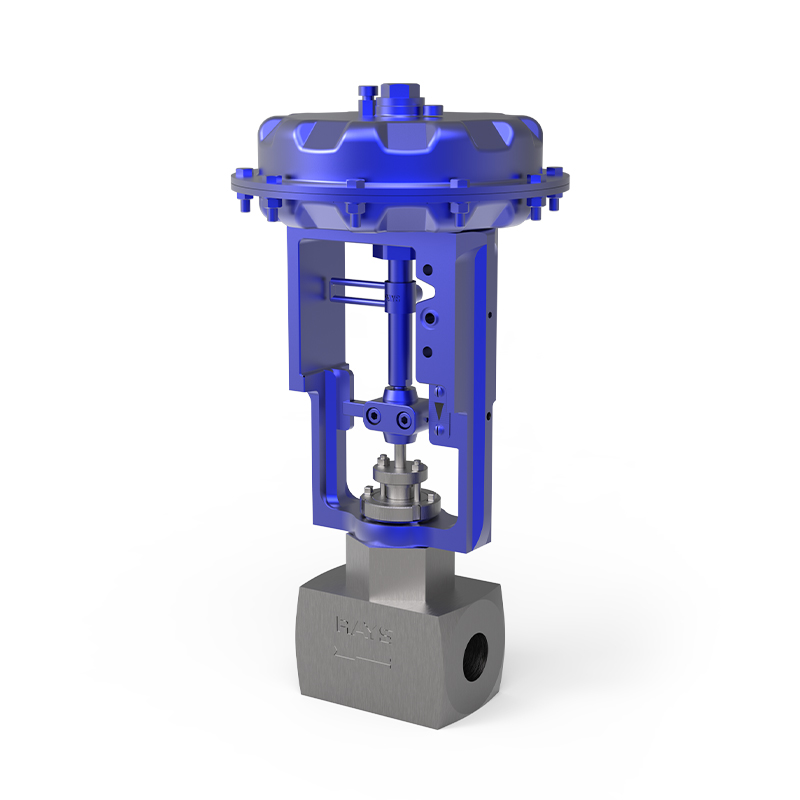

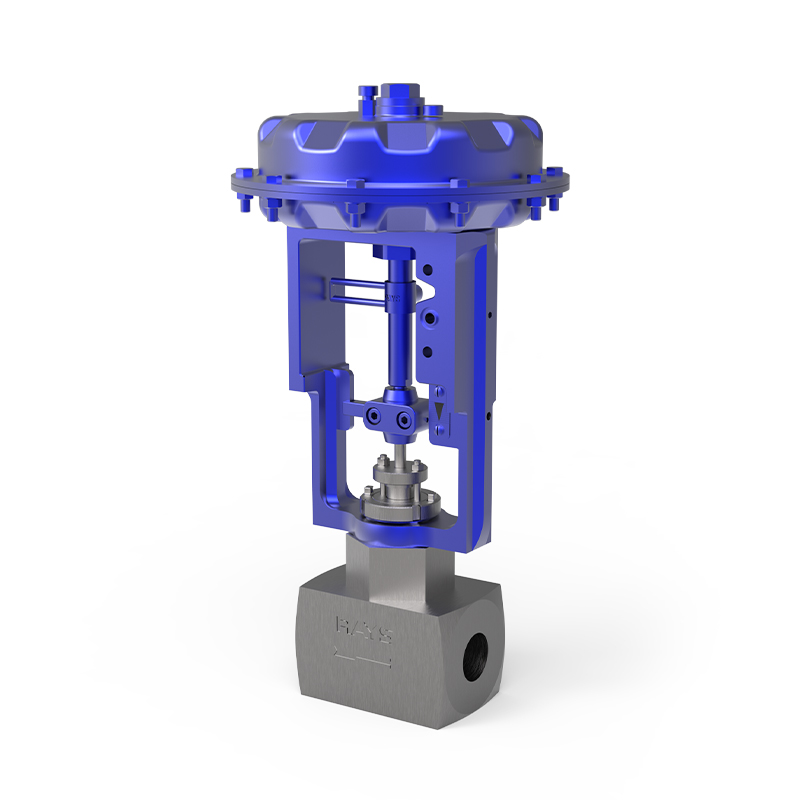

CHM701 High-pressure Micro-flow Single-seat Control Valve

The CHM701 High-pressure Micro-flow Single-seat Control Valve is suitable for controlling the micro-flow regulation of temperature fluids and is applicable to high-pressure fluid scenarios with high leakage requirements. The valve body has an S-shaped streamlined channel, resulting in low pressure drop loss, wide adjustable range, and high accuracy of flow characteristics.

CH701 High-pressure Single-seat Control Valve

The CH701 high-pressure single-seat control valve is a type of valve with top-guided structure. The fluid passage of the valve body is in the shape of an S-flow line. It has low pressure drop loss, large flow capacity, wide adjustable range, large guiding area of the valve core guiding part, good shock resistance, and is suitable for high-pressure fluid applications with high leakage requirements.

CUT701 Cryogenic Single-seat Control Valve

The CUT701 Cryogenic Single-seat Control Valve is a valve with top-guided structure. This valve is mainly applied in the temperature range of -196°C to -100°C and the pressure range of CL150 to CL1500, and it can achieve the functions of regulation or cutting in a safe manner. It can be suitable for different medium requirements. The ultra-low temperature single-seat control valve is an ultra-low temperature piston-type valve, featuring a compact valve body structure, small form, a fluid channel in S-flow line shape, low pressure drop loss, large flow rate, wide adjustable range, high accuracy of flow characteristic curve, large guiding area of the valve core, and good shock resistance.

CJ701 Jacketed Single-seat Control Valve

The CJ701 Jacketed Single-seat Control Valve is a derivative product of the C701 single-seat control valve. It is suitable for applications where the crystallization temperature of the medium is higher than the normal temperature, or where the viscosity of the fluid increases or solidifies due to a decrease in temperature. In addition to the advantages of the C701 single-seat control valve, it also has the function of using steam for heating and insulation to prevent material crystallization and solidification.

CF701 PTFE-lined Single-seat Control Valve

CF701 PTFE-lined Single-seat Control Valve’s inner cavity, valve core, valve stem and other parts of the CF701 PTFE-lined Single-seat Control Valve that come into contact with the medium are all lined with polyperfluoroethylene propylene (referred to as F46), which is resistant to corrosion and aging. It is widely used in industries such as chemical engineering, petroleum, metallurgy, medicine, and power for process control of strong corrosive media like acids and alkalis, as well as toxic and volatile media. It adopts a dual sealing system of polytetrafluoroethylene bellows and packing to ensure no leakage.

C700 Series Single Seated Control Valve is a top-guided structure control valve, used in equipment that can achieve air opening or air closing. The fluid channel of the valve body is in an S-shaped streamlined shape, featuring low pressure drop loss, large flow rate, wide adjustable range, high accuracy of the flow characteristic curve, large guiding area of the valve core, and good vibration resistance. The control valve is equipped with a multi-spring diaphragm actuator, which features a compact structure and large output force. It can be used to control various fluids with different pressures and temperatures.

This series of products is compact in structure, small in size, the fluid channel is streamlined in S, the flow characteristic curve is accurate, and the realization of larger CV. Quick replacement and easy maintenance. With RSMF multi-spring pneumatic film actuator, large thrust, strong rigidity, sensitive action, high-precision positioning, fast response, convenient and strong, long service life.

Material: WCB、WCC、LCB、LCC、WC6、WC9、CF8、CF8M、CF3、CF3M

Nominal Size: DN15~300

NPS 1/2”~12”

Pressure rating: PN16、PN25、PN40、PN63、PN100 ASME:CL150、CL300、CL600

High pressure:CL900 、CL1500 、CL2500

Temperature Range: Standard Temperature: -17℃~+230℃

High-temperature EI:+230℃~+525℃

Low-temperature LE-I:-45℃~-17℃

LE-II:-100℃~-45℃

LE-III:-196℃~-100℃

Operator: Pneumatic, Electric, Manual, etc

Application range: Suitable for switching the flow direction of the medium in pipeline systems such as water supply, petrochemical, metallurgy, mining, textile, energy, paper, food, steel, etc.Also, for shunting or mixing fluids.

The Power Plant Check Valve has small fluid resistance, the medium channel inside the valve body is straight through, and the flow direction of the medium does not change when it flows through the check valve. The pressure self-tightening seal is used, and the two ends of the valve are usually welded. The valve flap closes quickly, the water hammer pressure is small, the body structure is simple, the production process is good, the sealing performance is good, and the sealing surface is less eroded when fully opened. A wide range of applications.

The DBB Plug Valve is a high-performance fluid control device. It adopts advanced track-guided technology to achieve low-torque opening and closing and zero-leakage sealing. This valve is specially designed for harsh working conditions and is suitable for key fields such as petroleum, chemical industry, power and long-distance pipelines. It can meet the complex working conditions such as high pressure, high temperature, corrosive media, and frequent operations. (also known as the general valve) is a high-performance fluid control device. It adopts advanced track-guided technology to achieve low-torque opening and closing and zero-leakage sealing. This valve is specially designed for harsh working conditions and is suitable for key fields such as petroleum, chemical industry, power, and long-distance pipelines. It can meet the complex working conditions such as high pressure, high temperature, corrosive media, and frequent operations.

The Sampling Double Disc Gate Valve is an efficient valve specifically designed for industrial sampling. It features a double-gate structure that ensures reliable sealing and precise sampling control. The unique double-gate design guarantees stable media flow during the sampling process while effectively preventing leakage and contamination. This valve is widely used in industries such as chemical and pharmaceutical, especially for sampling inspections in reactors under crystallization conditions.