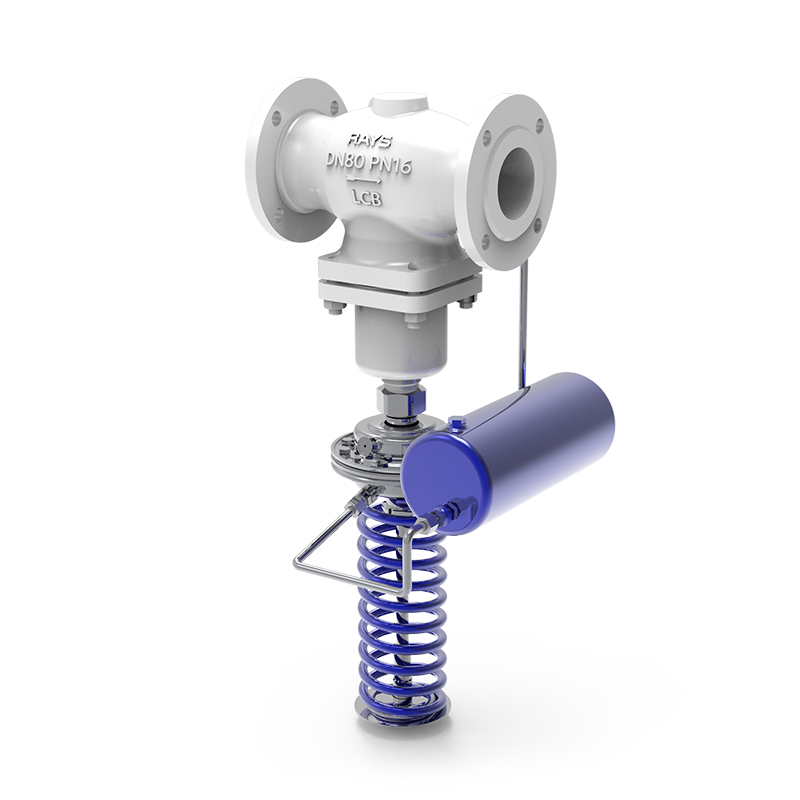

SO-26001、SO-26101、SO-26201 Self-operated Differential Pressure Regulator for Downstream Control

An energy-saving control valve without external energy supply, used for non-corrosive liquids and gases with a temperature of ≤ 200℃. It is a pressure differential control device at the valve outlet. When the pressure differential increases, the valve closes.

SO-26002、SO-26102、SO-26202 Self-operated Differential Pressure Regulator for Upstream Control

An energy-saving control valve without external energy sources, used for non-corrosive liquids and gases with a temperature of ≤ 200℃ and a valve-before differential pressure control device. The valve opens when the differential pressure increases.

An energy-saving control valve without external energy supply, used for non-corrosive liquids and gases with a temperature of ≤ 200℃ for differential pressure control devices. The valve opens or closes when the differential pressure increases.

Low maintenance, direct control of the medium, energy-saving control valve without external energy supply

Stainless steel bellows pressure-balancing type, with small unbalanced force and high sensitivity

Supports internal and external pressure tapping

Wide range of set points, adjustable set points can be conveniently adjusted by adjusting the nut

For high sealing requirements, use soft-sealing valve core

Standard modular design, with high levels of standardization, series, and generalization

Material: WCB、CF8、CF8M

Nominal Size: DN15~250mm

Pressure Rate: PN1.6~PN4.0MPa

Voltage Regulating Range:ZA3:0.1~0.6Mpa、0.015~0.15Mpa、0.05~0.3Mpa、0.01~0.07Mpa、0.005~0.035Mpa

ZA4:0.1~0.5Mpa、0.005~0.12Mpa、0.05~0.25Mpa、0.01~0.06Mpa、0.005~0.035 Mpa

Temperature Range: ≤200℃

Operator: Self-Pressurized

Application range: This is applicable to automatic control systems without (or where driving energy cannot be used) in industrial processes such as water supply, petrochemicals, heating and thermal supply, energy, papermaking, food, and steel production. It is particularly suitable for automatic control system devices in natural gas extraction and transportation or gas transmission.

The Concentric butterfly valve is an industrial valve used for the on-off and flow control of pipeline systems. It is widely applied in fields such as petroleum, chemical industry, metallurgy, and hydropower. Its core structural feature is that the axis of the valve stem, the center of the butterfly plate, and the center of the body are on the same axis, featuring simple manufacturing and balanced opening and closing torque. By selecting different materials for the valve plate, valve stem, and sealing seat, it can be adapted to various different working environments, such as desulfurization, vacuum, and seawater desalination systems.

This series of products features a compact structure, small size, and S-shaped fluid channels. The valve core adopts a pressure-balancing structure, with high accuracy of the flow characteristic curve and the ability to achieve a larger CV. It can be quickly replaced, is stable and reliable, and is easy to maintain. A smaller actuating force can control a high pressure difference. There is a sealing ring between the valve core and the valve cage, significantly reducing the leakage. It is equipped with the RSMF series multi-spring pneumatic diaphragm actuator, which has a large thrust, strong steel strength, sensitive action, high-precision positioning, fast response, convenient and sturdy, and a long service life.

RAYS PDS Ball Valve is designed for extreme conditions characterized by high temperatures, high pressures, and abrasive media. Manufactured from premium alloy steel and enhanced with advanced hardening techniques, it offers exceptional wear resistance for both the ball and the seat. The hard seal design ensures superior sealing performance in harsh environments. Additionally, the valve features a robust construction and is easy to operate and maintain, significantly reducing maintenance costs. It is an ideal choice for heavy industries such as petrochemicals, power generation, and mining.