Recently, the overseas large-scale chemical plant equipment supply project undertaken by RAYS Company has achieved significant progress, with some Triple Eccentric Butterfly Valves and control valves already packed and delivered to the client. The project involved a total order of 202 valves. As one of the critical chemical infrastructure projects in Europe, the client imposed extremely high requirements for equipment reliability, safety, and environmental adaptability. Leveraging its extensive experience in valve solutions for ultra-high-pressure and highly corrosive conditions, RAYS successfully secured the bid for this project.

The delivered Triple Eccentric Butterfly Valves feature notable advantages such as large diameters (up to DN2600) and bidirectional zero-leakage sealing, specifically designed for the demanding conditions of the chemical industry to ensure long-term stable operation in complex environments. To enhance sealing performance, RAYS adopted an elastic sealing structure in the design, significantly reducing maintenance frequency and operational costs. Additionally, all valves are equipped with an anti-stem blowout structure, complying with API 609 safety standards, further reinforcing overall system safety. The thickened valve stem and reinforced disc design ensure the stiffness and strength required for sealing under high-pressure conditions, enabling superior sealing performance in both forward and reverse directions.

The valves delivered in this batch underwent comprehensive design optimization, strictly adhering to the ASME B16.34 standard. RAYS' technical team utilized 3D simulation analysis technology, resulting in valves that are approximately 1.2–1.5 times heavier than those of competitors in the same specification range. The optimized valve body structure significantly enhances strength, providing a higher safety margin beyond standard requirements and exceeding industry averages.

Furthermore, the internal flow passage design was optimized using fluid analysis modules (Creo Flow Analysis) and fluid dynamics simulations. Numerical simulations of the internal medium flow field were conducted to ensure maximum flow capacity with minimal resistance while meeting the strength and stiffness requirements for sealing. This achieves the optimal Cv value, reducing energy consumption.

Additionally, Finite Element Analysis (FEA) was employed to address the project’s specific operational requirements, incorporating customized designs to resolve the challenge of reverse sealing in butterfly valves.

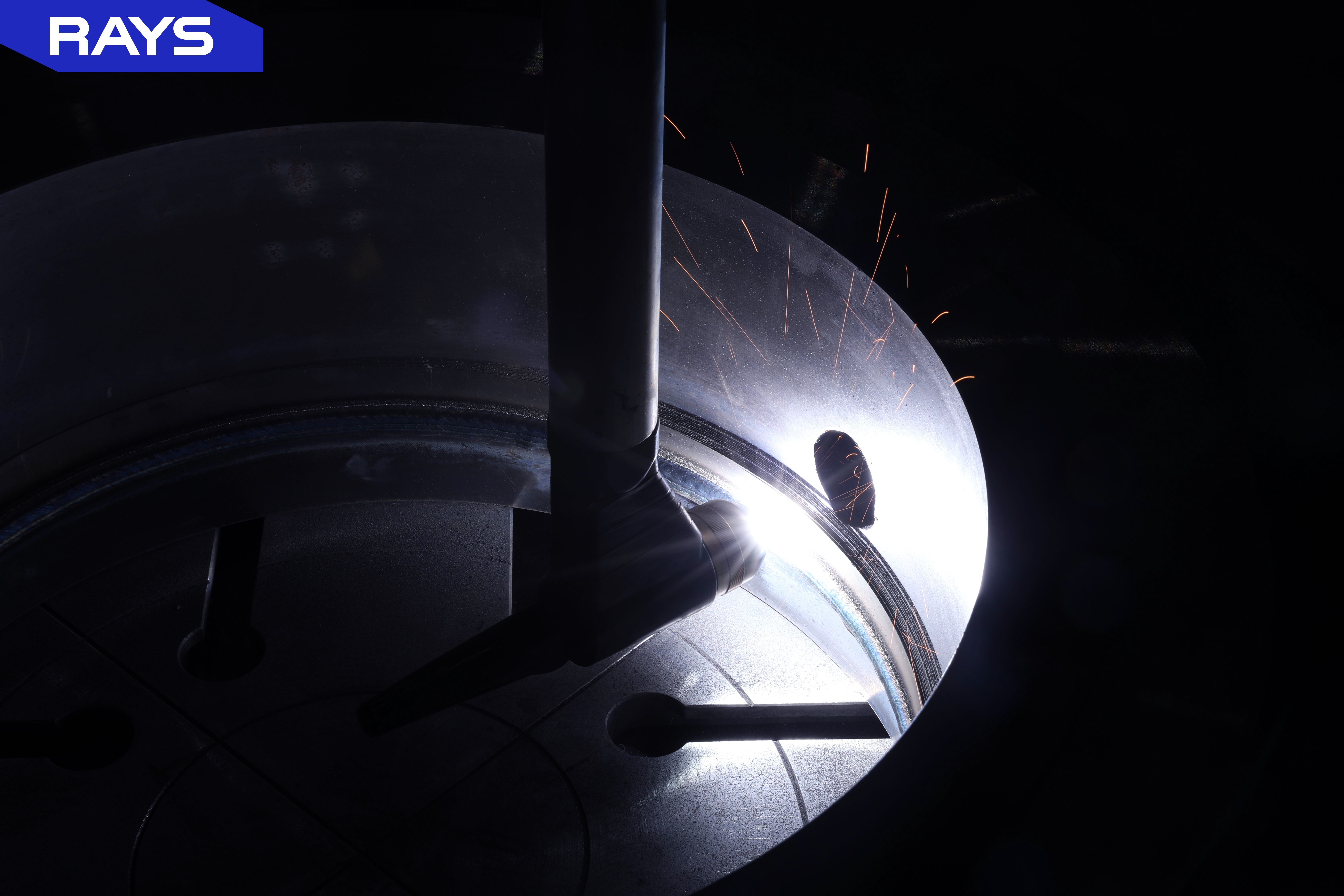

To ensure product quality, RAYS implemented rigorous inspections at every critical manufacturing stage, including 3D scanning for dimensional verification and high-pressure sealing tests. The project client and a third-party inspection agency have completed the Factory Acceptance Test (FAT) at the Alpha facility. The test results confirmed that all valves meet the ISO 5288 and EN 12266-1 Grade A standards for bidirectional sealing performance, fully satisfying the technical requirements of international high-end projects.

Moving forward, RAYS will continue to optimize product performance, providing safer and more efficient valve solutions for the chemical, energy, and other industries.