The global energy industry’s eyes are on Moscow.

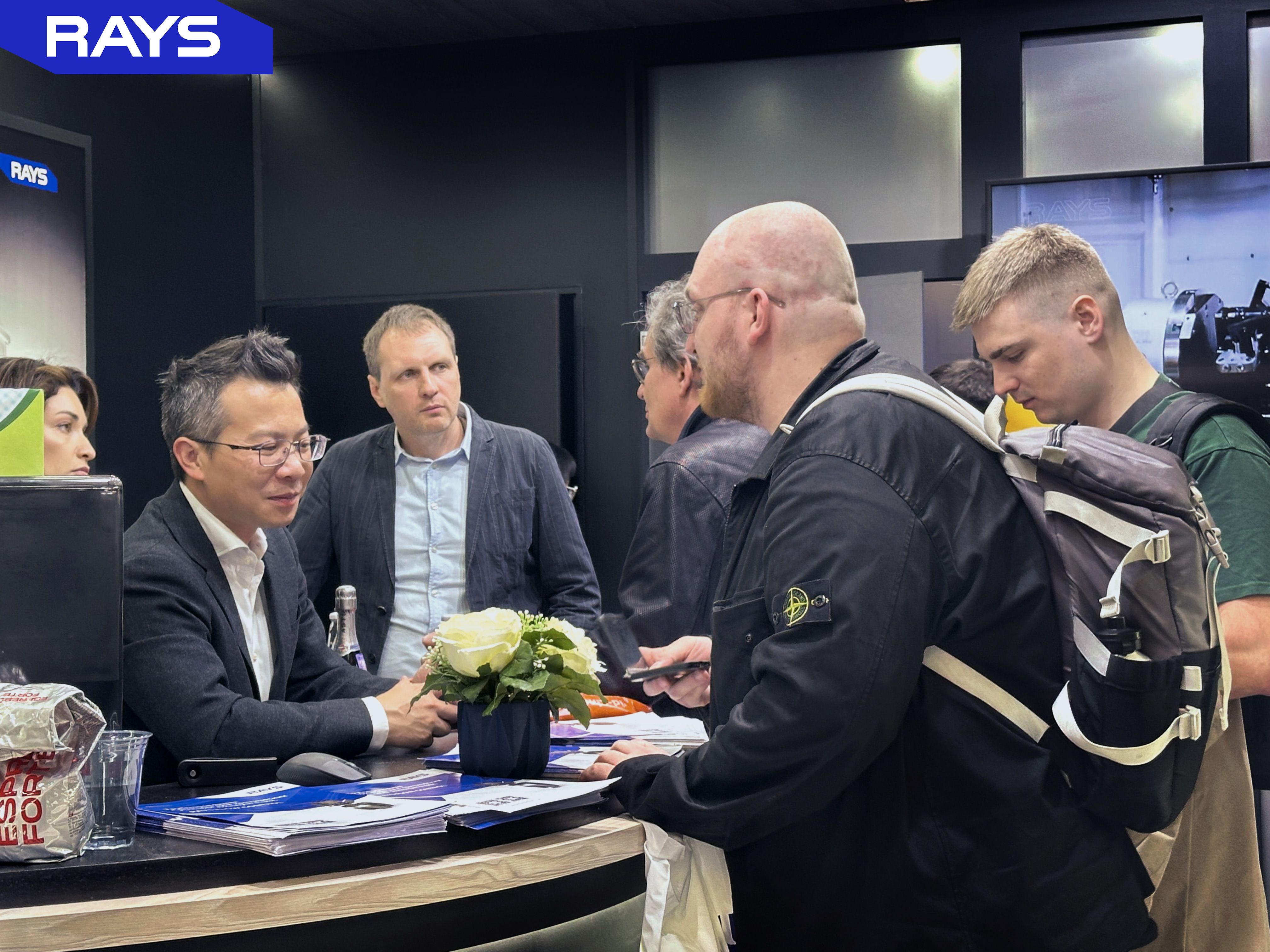

From April 14th to 17th, RAYS confidently showcased its solutions at the NEFTEGAZ exhibition, standing alongside over 1,200 exhibitors from 45 countries. As the largest oil and gas event in Eastern Europe, this year’s NEFTEGAZ attracted more than 30,000 professional visitors. RAYS‘ booth left a lasting impression on Eastern European clients with its distinctive brand image and cutting-edge technical expertise.

RAYS Products at the Exhibition

Self-Developed Cryogenic Valves in the Spotlight

RAYS’ independently developed cryogenic valve series, designed for extreme cold and ultra-low temperature conditions, garnered significant attention in the Russian market. The material selection and manufacturing processes of these cryogenic products must withstand continuous or sudden temperature variations to meet the demands of harsh environments.

In terms of materials, RAYS cryogenic valves utilize specialized materials such as low-temperature steel and austenitic stainless steel (e.g., SS304, SS316L). Austenitic stainless steel, after undergoing multiple deep cryogenic treatments, can perfectly adapt to ultra-low temperature environments as low as -196°C (liquid nitrogen temperature).

Structurally, the valves feature a dual-sealing system combining lip seals with graphite. The extended bonnet design includes an external drip plate installed outside the insulation layer, effectively preventing condensation from dripping onto the valve’s insulation, bolts, or critical components—thereby protecting the valve parts, maintaining insulation integrity, and minimizing cold loss.

For quality control, RAYS Alpha production base is equipped with a dedicated cryogenic laboratory. Strictly adhering to international standards such as BS 6364 and MSS SP-77/200, the valves undergo rigorous testing, including -196°C leakage rate assessment, torque testing, low-temperature impact tests, and actuator functionality checks. These tests simulate real-world conditions to ensure optimal material and process compatibility, guaranteeing compliance with international standards and customer requirements.

Through material optimization, structural innovation, and stringent testing, RAYS cryogenic valve series delivers exceptional durability and performance in cold and ultra-low temperature environments, ensuring zero-leakage safety for global LNG projects.

Deepening Roots in Russia, Empowering Eastern Europe’s Fluid Equipment Upgrades

The Russian market is currently in a critical phase of equipment upgrades. RAYS has established a local professional team in Russia to strengthen ties with the Eastern European market, providing tailored support and solutions. By combining localized service teams with customized R&D, RAYS has already helped multiple local projects achieve cost efficiency and performance improvements.

This exhibition resulted in over 20 potential client leads, further elevating B2B collaborations. Moving forward, RAYS will continue to solidify its pivotal role in the Russian market, driving advancements in fluid equipment across Eastern Europe.

A Successful Conclusion to the Moscow Journey!